Nitstansvägen 2

451 55 Uddevalla

Based on Scandinavian Enviro Systems’ leading recycling technology, Antin Infrastructure Partners, Michelin and Scandinavian Enviro Systems have joined forces and created a tire recycling joint venture company. The JV’s first large-scale recycling facility for end-of-life tires is now being built in Uddevalla and by 2030 it plans to establish plants across Europe with a total recycling capacity of 1 million tons. This is an exciting and rewarding opportunity to work at a plant that turn waste into valuable raw materials and contribute positively to the environment and the community.

Our bold growth plan needs support from potential colleagues like you, who want to make a real impact.

Scandinavian Enviro Systems, developer of the recycling technology and co-owner of the JV, operates since ten years a state-of-the-art tire recycling test facility in Åsensbruk. The plant in Uddevalla will be a significant scale-up and create the basis for taking the technology globally.

Stay updated with us, as we will hire more people for the recycle factory, such as IT Contractor, Administration Support, Quality Manager, Logistic Manager, Logistic Planner, Logistic Coordinator, Logistic Operators, Lab Assistant and others. If you are interested in any of these positions, feel free to apply using the spontaneous application.

Why did you choose to work at Tyre?

I was captivated by TRU/Enviro as soon as I heard about the planned initiative in Uddevalla, which is now under construction after many years of effort and the intension to expand into Europe. It’s a company that will be at the forefront of the green transition with its proprietary technology, significantly reducing the climate footprint. Being part of such a monumental industrial project in a new sector is a once-in-a-lifetime opportunity!

Why should someone consider starting their career at Tyre?

At TRU, you’ll have a key role in launching and managing a brand-new facility. You'll be instrumental in setting up the work processes and routines that will form the backbone of our success and support our growth across Europe.

What motivated the establishment of TRU and its focus on the green transition?

Our main goal at Enviro/TRU was to tackle the challenge of recycling end-of-life tires and turning them back into valuable materials for the tire and rubber industries. Previously, these tires were mostly burned for fuel in power plants and cement kilns. Working with us means making a real impact on the environment.

What innovative strategies or technologies have you implemented to support your vision of a green transition?

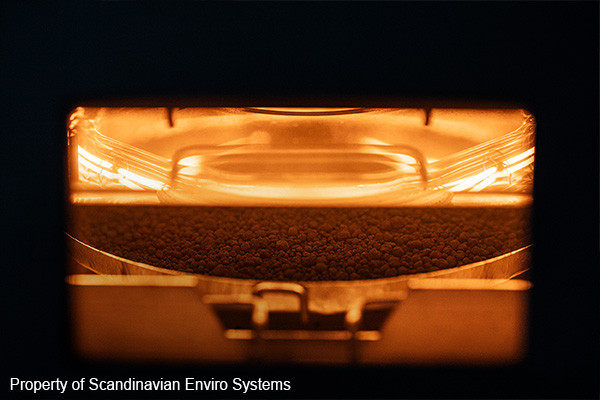

We are realizing our plan with Enviro´s patented and cutting-edge pyrolysis process. This innovation underscores our commitment to leading the industry toward a greener future.

How do you collaborate with other stakeholders to maximize impact and disseminate your vision?

We work closely with our customers and feed-stock suppliers who are responsible for collecting end-of-life tires, ensuring a sustainable supply chain that supports our environmental goals.

What are your concrete goals for the company’s development and growth over the next decade?

With our new parent company structure, including TRU, Enviro, and Antin, our target is to build capacity in Europe to process 1 million tons of end-of-life tires by 2030.

Looking ahead, what role do you see yourself and Tyre playing in the global green transition over the next ten years? What impact do you anticipate?

We hope to be a major player in our field. As the demand for tire recycling grows, there’s room for more innovation and competition. We plan to lead this charge, making a significant environmental contribution.

A world without waste. Our goal is to foster a cleaner and greener planet by minimizing the environmental footprint of tyre waste. We aim to provide a profitable and sustainable tyre recycling solution that meets the highest standards of quality, safety, and environmental performance. We are committed to innovation, excellence, customer satisfaction, and teamwork.

Waste is misuse of resources. Enviro’s technology can not only reduce waste, but also make use of the valuable raw materials included and transform them to revenue, which benefits the environment, the economy and surrounding society. It is a matter of sustainability in several dimensions through partnerships.

Our mission is to lead the way in enabling circularity for valuable raw materials, positioning sustainability at the forefront of all business strategies.

Our process transforms old tyres into new ones by extracting carbon black, utilizing recycled oil, and creating synthetic rubber from natural rubber. This approach aims to produce nearly all-green tyres, addressing the global waste tyre issue and helping the tyre industry meet its extended producer responsibility.

While complete circularity is not feasible for the fuel sector, using recycled oil as a feedstock for biodiesel presents a more climate-friendly option. Biodiesel derived from recycled materials offers a viable alternative for the airline industry, which currently cannot transition to electric power like the automotive sector.

The oil produced through our recycling process contains approximately 50% biological content due to the high natural rubber content in many tyres. This makes it a valuable and attractive resource for the refinery and chemical markets. Utilizing recycled oil significantly reduces our carbon footprint and contributes to a greener planet.

Traditionally, the plastic industry has relied on fossil resources. Today, it is increasingly using renewable raw materials, such as those from the forest industry, to produce the gas needed for plastic production. Our recycled oil can be converted into synthetic gas, enabling the production of plastic that can be continuously recycled.

To achieve climate neutrality by 2050, the chemical industry must lower its CO2 emissions by adopting renewable or recycled raw materials, or both. Our recycled oil provides an alternative to crude oil, facilitating the creation of products from waste and contributing to the industry's sustainability goals.

Nitstansvägen 2

451 55 Uddevalla

Powered by Masterhelp